Present technological map was done in accordance with 20022.5-93 State Standard.

1. Treatment is manufactured by using technological instructions, in accordance with 20022.1 State Standard by Pressure-Pressure-Vacuum method. This method is applied for treated sleepers/railroad ties, transfer point/switch and bridge beams, poles and wooden supports of electric and communication transmissions.

2. Treatment of the timber, such as wooden sleepers for wide railway tracks, transfer point/switch wooden beams, bridge beams is characterized by general absorption of the protecting agent, applying antiseptic as a coal oil in accordance with 2770-74 State Standard. The antiseptic is kept in separated reservoir.

3. The humidity of the lumber is no more than 25% before treatment.

4. Preliminary air pressure must be from 0.2(2) to 0.4 MPа (4 kgс/cm2). Working liquid pressure for coniferous species of lumber must be no more than 1.2 МPа (12kgс/cm2), for firm deciduous species of lumber it is no more than 1.4МPа (14 kg/cm2). The depth of initial and last vacuum is 0.08 МPа (0.8 kgс/cm2).

5. The temperature of the protecting agent during the period of liquid pressure is no less than 90 C.

6. The norm of absorbing the antiseptic is 96 kg/cubic m.

7. Average depth of saturation is 5 mm.

“Wooden sleepers/railroad ties for wide railway tracks” (type 1, type 2), “Treated wooden beams for transfer points/switches for wide railway tracks” (type 1, type 2), “Wooden bridge beams” are made using following technological norms and requirements of №78-2014, №8816-2003, №28450-90, №20022.5-93 State Standard.

Technological manufacturing process consists of the following operations:

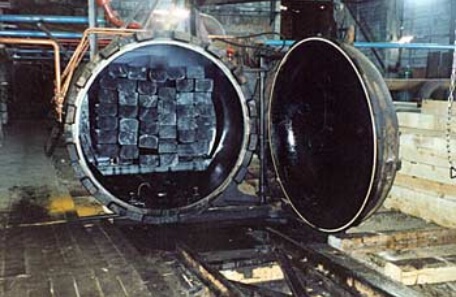

1. Rolling up 4 narrow-gauge railway cars containing the sleepers (from 130 to 168 items in each load depending on the type) into a treatment cylinder. Closing the cover air tight.

2. Heating the antiseptic in heat exchange unit by means of a steam coil to the temperature of 95-100 Celsius, but less the temperature of a flash-point by 5 Celsius.

3. Filling the treatment cylinder with hot antiseptic using the pump with immediate circulation of air inside the system.

4. Creating liquid pressure of antiseptic using the ПДВ pump up to 6 kg/cm2.

5. The period of liquid pressure.

6. Lowering the pressure.

7. Creating the air pressure at 2 kg/cm.

8. Maintaining the air pressure at 2 kg/cm.

9. Thorough emptying of the treatment cylinder from the remaining antiseptic.

10. Unloading the cars from the cylinder.